Production under clean room conditions

By continuously adhering to the high quality standards of the aerospace and automotive industries and processing temperature-sensitive printing pastes, we guarantee consistently precise temperature control. Production takes place consistently under clean room conditions to ensure the highest product quality and process reliability.

Our production machines

Our production machines are state-of-the-art and guarantee the exact dimensional accuracy and quality of our products through precise printing processes and high-precision laser cutting technology.

Quality control

Our quality management is based on the highest standards of the aviation and automotive industries. We ensure strict compliance with these requirements through regular audits by our clients as well as by independent external auditors..

Materials

We work exclusively with high-quality materials

Film substrates

Our printed resistive heating elements are manufactured on extremely thin and flexible film materials (substrates) that often have a thickness of only 0.1 mm.

These film substrates are crucial for high design flexibility, as they allow the heating element to be adapted to any shape and contour. They also serve as carriers for the heating elements and enable complete encapsulation. The choice of specific film material depends on the required temperature resistance and the subsequent processing (such as laminating or injection moulding)..

Conductive and printable pastes

In our screen printing processes, we use, among other things, a conductive silver paste with high electrical conductivity (typical sheet resistance: 0.0057 ohm/sq at 25µm) and good mechanical stability. The paste is compatible with common dielectrics and carbon inks and is suitable for use in combined material systems. It offers high viscosity, good coverage (up to 10.6m²/kg at 10µm layer thickness), and is optimized for industrial drying processes (e.g., 15 minutes at 120°C). This makes it particularly suitable for precise and reproducible applications in the field of functional layer systems.

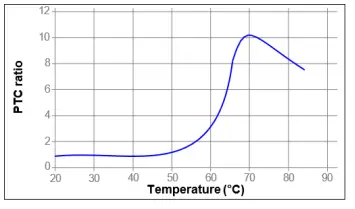

A printable polymer-based PTC ink is also used to produce self-regulating heating elements for low-voltage applications (<50V). The material features a positive temperature coefficient with a PTC ratio of over 8 and achieves a self-regulating temperature of approximately 60°C, typically on polyester films.

The processing is carried out using the screen printing method. The high thixotropy (TI: 7.0) and a theoretical material application of up to 48 m²/kg at a layer thickness of 10 µm enable a uniform and reproducible application on common substrates..