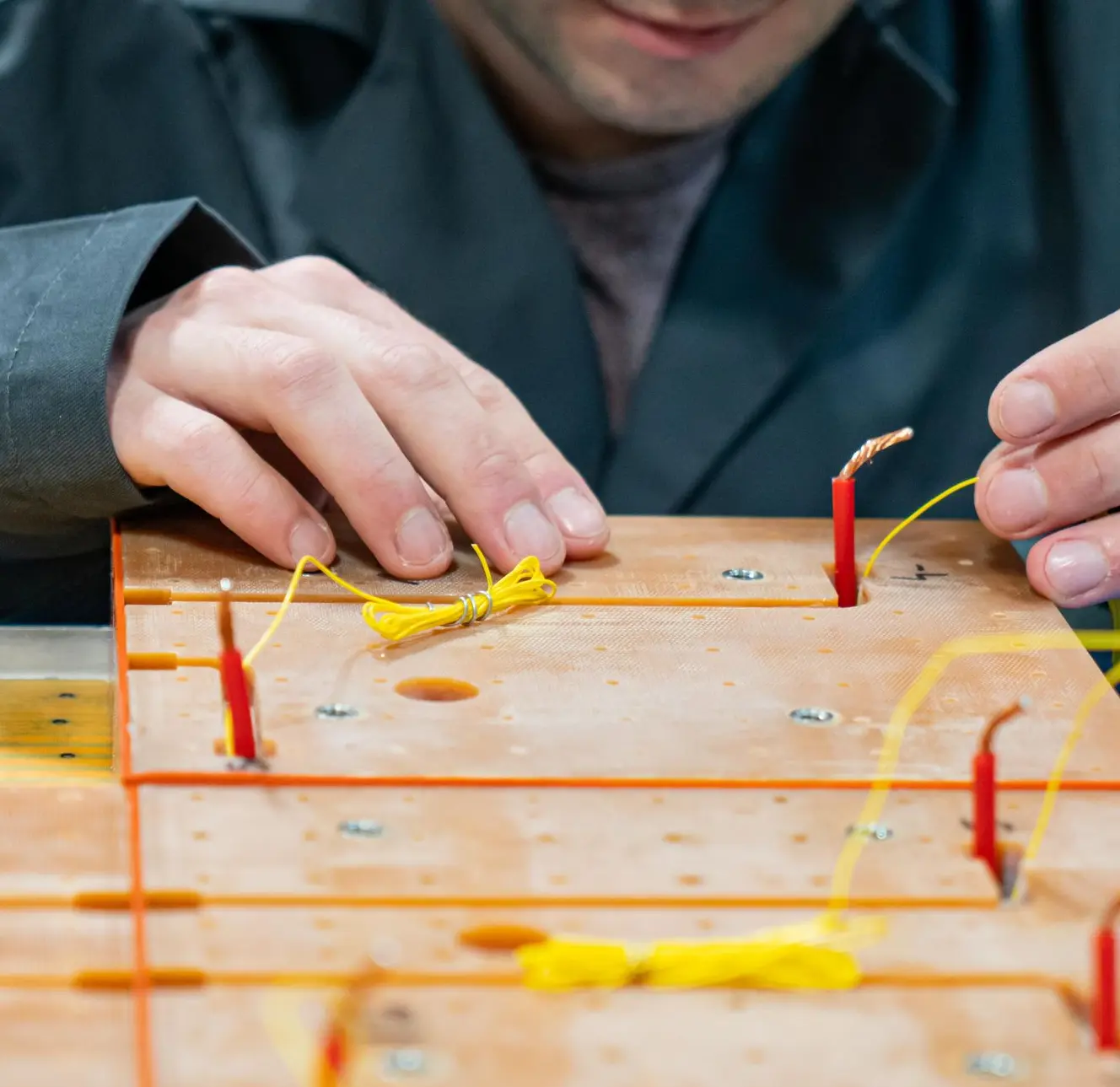

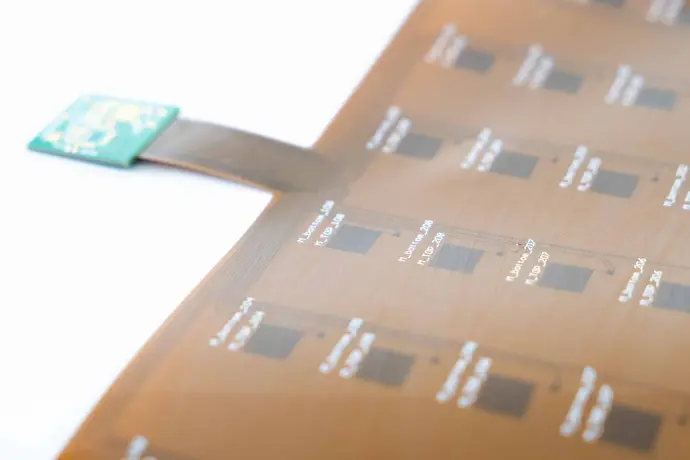

Heater for integration into soft surfaces (underfloor heating)

The optimal temperature of the materials around us is crucial for our well-being, whether in public transport, in the car, or in aviation..

Application areas in the vehicle:

- Heated center armrests

- Heated sun visors

- Heated armrests

- Heated seats

These soft, textile- or plastic-covered components enable direct and energy-efficient heat dissipation through integrated radiant heating.

Especially in electric vehicles, where traditional interior heating via air heating is considered inefficient, the targeted heating of contact surfaces offers a significantly more effective solution.

Transferability to other means of transport:

ATT is already active in:

- aviation (e.g. with heated seats)

- the automotive (e.g. heated sun visors, seats and armrests)

- the rail vehicle industry (heated interior and seating)

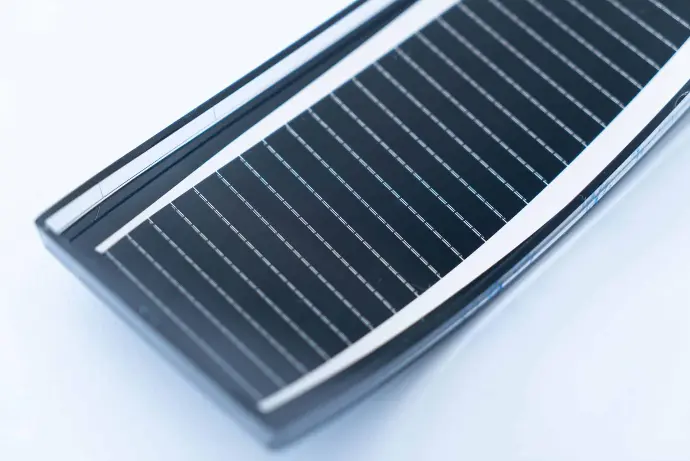

Heater for integration into hard surfaces (surface heating)

ATT's heating technology enables direct integration into solid, structural components in a wide range of industries. Embedding it into hard surfaces enables targeted, flat heating solutions – whether for functional maintenance, comfort, or targeted temperature control in technical, industrial, or everyday applications.

Example applications:

- Radar heaters in the area of (partially) autonomous driving (e.g. front grille, bumper)

- Vehicle interior components such as glove compartments, door or footwell panels

- Forming technology for plastic cups in food packaging

- Warming cups for bread and pastries in shopfitting and food retail

When integrating heaters into hard surfaces in the automotive sector, one application area stands out as a particular challenge: the heating of protective covers for radar systems for autonomous driving.

The key challenge in surface heating in radar technology is to obtain signals precisely at the wavelength of the radar sensors – without interference or distortion. This is the only way to ensure reliable and clear signal transmission that meets the high demands of modern radar systems.

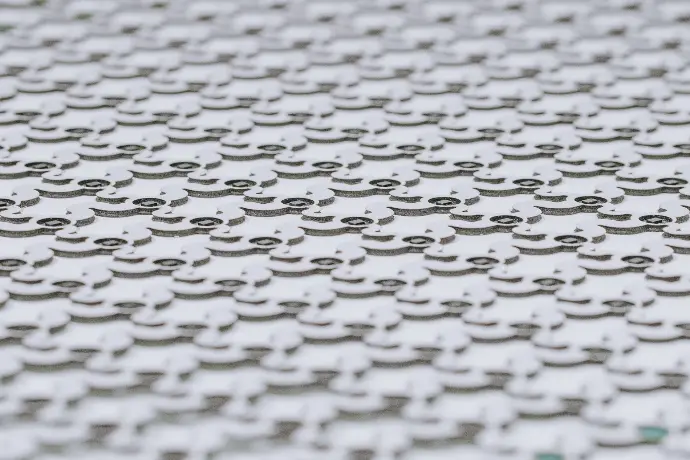

Sensors & measuring systems (temperature sensors)

ATT develops and integrates advanced sensor technologies for precise temperature measurement and functional monitoring in demanding environments. The company focuses primarily on printed NTC temperature sensors that can be embedded directly into thin heating foils or surfaces. These ultra-flat sensors enable precise temperature control and offer high reliability – even under dynamic thermal loads.

The technology is typically applied in the automotive sector, particularly in vehicle interior climate control and as a seat occupancy sensor. Furthermore, it is used in ice detection systems, for example, for monitoring AdBlue tanks. A central area of application is radar technology for driver assistance systems, where sensors and heating functions are combined to efficiently keep critical sensor surfaces free from ice, snow, or condensate..

Industrial solutions

An example from the packaging industry

ATT offers innovative heating plate systems that have been specifically developed for the packaging industry. This technology significantly accelerates the heating process of plastic films while ensuring precise and uniform temperature control..

This technology optimises the production of food-safe cups using the deep drawing process. We develop and supply the entire control unit, including customised control cabinets, which enable precise function and temperature control. This provides ATT with a comprehensive system solution from a single source, sustainably improving efficiency and quality in food packaging..

Battery management systems

ATT offers specialised heating and sensor technologies that can be used in the context of battery management systems to precisely monitor and control the temperature of battery cells.

The integration of printed temperature sensors (especially NTC sensors) enables accurate temperature measurement directly at the cells or battery modules. This is essential to keep the battery within an optimal temperature range, extend its lifespan, and minimise safety risks from overheating or undercooling..

Furthermore, the heating systems developed by ATT can be specifically used to protect battery packs in cold environments from performance loss or damage due to excessively low temperatures. By combining heating and sensor technology, ATT thus offers a comprehensive solution for temperature control in modern battery management systems, which is particularly important for electric vehicles.

Manufacturing with the highest quality standards

ATT bears significant responsibility for the quality of its products, particularly in the aviation and automotive industries, by adhering to and exceeding strict safety standards.

In aviation, all components must withstand extreme conditions, which is why the use of high-quality materials and continuous research are essential to ensure passenger safety. In the automotive sector, it is important to meet both safety and environmental standards, which is achieved through proactive material selection and production optimisation..

Through meticulous quality controls, ATT demonstrates its commitment to the highest safety and quality standards, thereby maintaining the trust of its customers in the long term.. ISO 9001 Certification