Integration und transparente Hinterspritzung

Im Speziellen für autonomes Fahren Radar - gedruckte elektronik transparent für radar - heizer - hinterspritzt mit kunststoff kontaktierung

U

Our production machines are state-of-the-art and guarantee the exact dimensional accuracy and quality of our products through precise printing processes and high-precision laser cutting technology.

Q

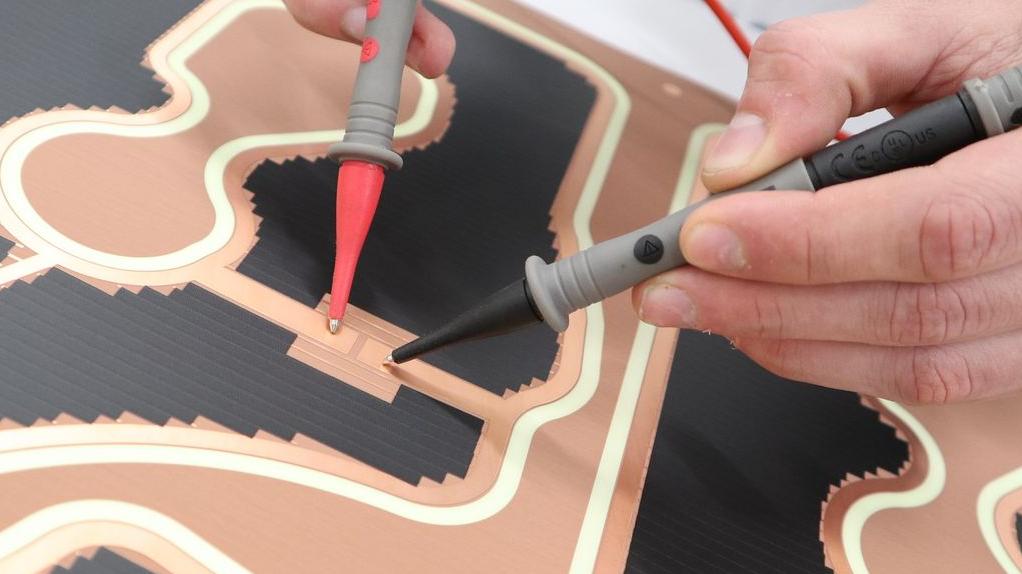

Our quality control is based on the demanding standards of the aviation and automotive industries, as we primarily operate in these sectors. To ensure compliance with these high standards, our quality management is subject to regular audits by our clients.

M

We work exclusively with high-quality materials, pastes and film substrates

Film substrates

The use of printed PTC (Positive Temperature Coefficient) polymers on film substrates allows for precise temperature control and efficient integration into various components. These systems are particularly advantageous for applications where space and weight savings, as well as uniform heat distribution, are critical.

Conductive and printable pastes

In our screen printing processes, we use, among other things, a conductive silver paste with high electrical conductivity (typical sheet resistance: 0.0057 ohm/sq at 25µm) and good mechanical stability. The paste is compatible with common dielectrics and carbon inks and is suitable for use in combined material systems. It offers high viscosity, good coverage (up to 10.6m²/kg at 10µm layer thickness), and is optimized for industrial drying processes (e.g., 15 minutes at 120°C). This makes it particularly suitable for precise and reproducible applications in the field of functional layer systems.

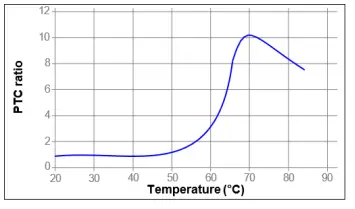

A printable polymer-based PTC ink is also used to produce self-regulating heating elements for low-voltage applications (<50V). The material features a positive temperature coefficient with a PTC ratio of over 8 and achieves a self-regulating temperature of approximately 60°C, typically on polyester films.

The ink has a resistivity of approximately 1,700 ohms/sq at a layer thickness of 25 µm and can be mixed with non-conductive pastes for resistance adjustment. It is compatible with conductive silver inks, allowing for the realization of hybrid functional structures.

Die Verarbeitung erfolgt im Siebdruckverfahren. Die hohe Thixotropie (TI: 7.0) und ein theoretischer Materialauftrag von bis zu 48 m²/kg bei 10 µm Schichtdicke ermöglichen eine gleichmäßige und reproduzierbare Applikation auf gängigen Substraten.